Rendering Process

|

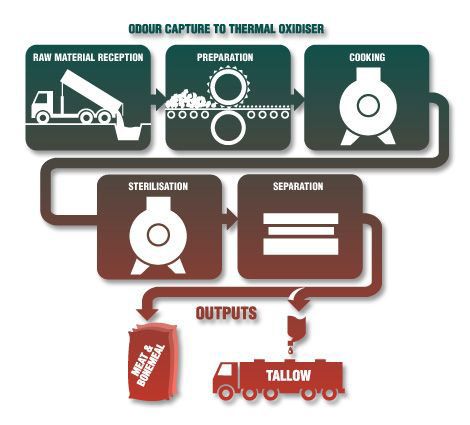

Animal by-products are discharged into hoppers that allow plant operators to combine soft offal and bone. This provides a mix that will allow optimal operation of equipment within the process. The by-products are sized by crushing to reduce particle sizes to less than 50mm in diameter.

Crushing allows for more uniform heating within the cooker. Once sized, the material is transferred to a steam-heated vessel that agitates and pre-cooks the material at 101-104 degrees centigrade.

After pre-cooking the animal by-products are conveyed for batch sterilisation which maintains a minimum temperature of 133 degrees centigrade, and a pressure of 3 bar for a period of 20 minutes as required by regulation EU 1774/2002, method 1. After exiting the steriliser, free fat is drained from the solid material as it is augered over screens en route to expeller presses.

The fat is further clarified by passing through decanters and a series of oscillating screens which remove small particles of residual meat and bone. The fat is then pumped to bulk storage tanks. Additional fat is squeezed from the solids as they pass through the expeller presses. This fat joins the free fat for clarification.

The solids contain the meat and bone residues and represent the protein and mineral content of the by-products. Both the fat (tallow) and the meat and bone meal are sterilised products once they leave the cooker and presses. The finished product is a fine granular material that is medium to light golden brown in colour.

Water vapour driven off the by-products in the pre-cookers and pressure sterilisers is passed through scrubbing equipment and the regenerative thermal oxidation system to minimise odours.